Precision-built for the ultimate experience

While others chase after trends, Festka stays true to its cutting-edge robotic technology and tube-to-tube system. This unique approach allows for fully custom geometry that far surpasses monocoque frames in quality. This results in a timeless functional design that never goes out of style.

Made in Europe

Engineered results

Where others end, we begin

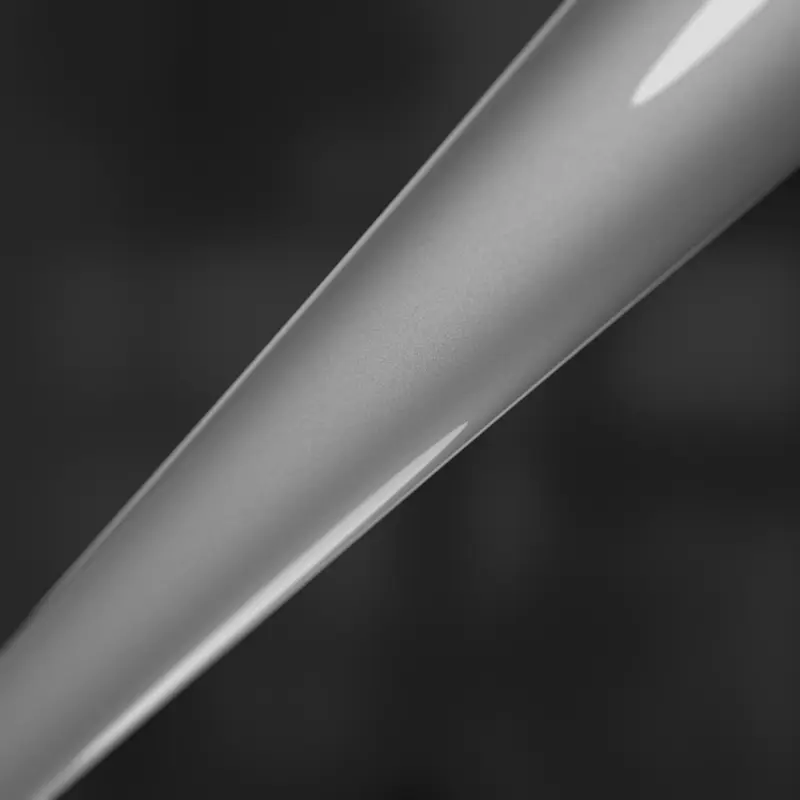

Our robotically woven tubes combine multiple layers of HS and UHM carbon fibers, precisely engineered for specific functions. The first layer provides stability, the second performance and the third torsional strength. Together, they create the perfect balance of pedaling efficiency and comfort. Though the production costs of these tubes are higher than those of complete monocoque frames, the unmatched quality is well worth it. Built to the technical standards of the aerospace industry, our carbon tubes share similarities with modern jets. Each layer is crafted from a single continuous strand of carbon filament, eliminating air bubbles, seams, and joined fibers. The CNC automated AFL (axial fiber laying) technology guarantees the highest quality for every tube produced.

Sharing know-how to encourage innovation

During development, we team up with experts whose know-how often goes well beyond the needs of cycling. Alongside our own engineers in the R&D team, we collaborate with university professors, PhD students, CEOs of tech companies, former professional cyclists, cycling enthusiasts, and skilled artisans to create a truly holistic cycling experience. Many of our innovations have stemmed from our collaborations, which have also led to partnerships with esteemed institutions like the European Space Agency and earned us a number of prestigious awards, including Deloitte’s European Rising Star.